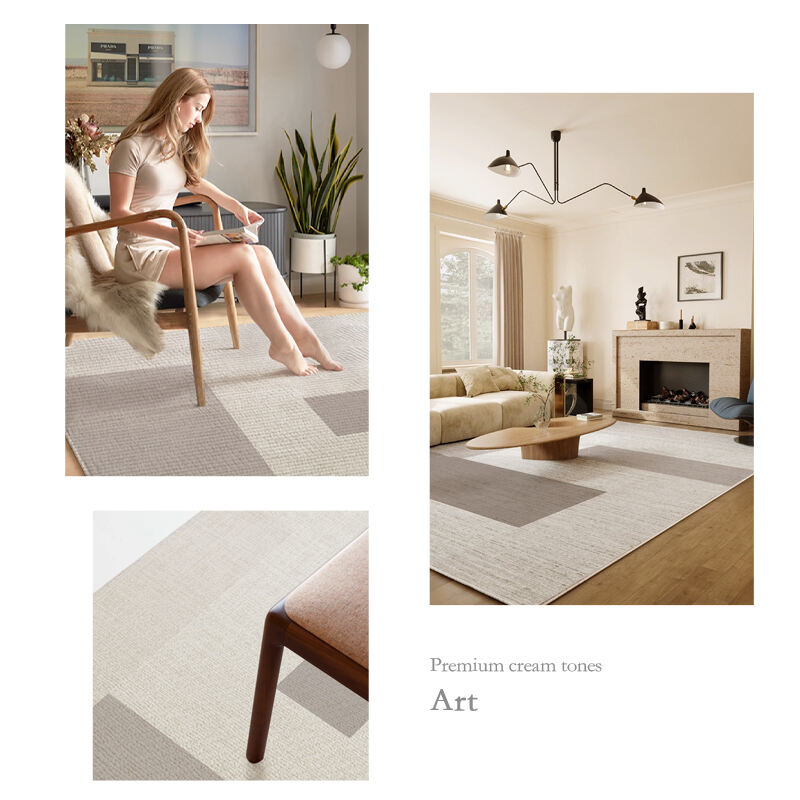

oem area rug

OEM area rugs represent a significant advancement in custom floor covering solutions, combining traditional craftsmanship with modern manufacturing capabilities. These rugs are specifically designed and produced according to client specifications, offering unparalleled flexibility in terms of size, pattern, material composition, and design elements. The manufacturing process employs state-of-the-art technology to ensure consistent quality while maintaining the ability to customize every aspect of the final product. These rugs feature advanced fiber technologies that enhance durability, stain resistance, and color fastness, making them suitable for both residential and commercial applications. The production process incorporates precision weaving techniques, allowing for intricate pattern reproduction and consistent pile height. Additionally, OEM area rugs often include specialized treatments for moisture resistance, anti-microbial properties, and enhanced texture retention, ensuring long-term performance in various environments. The versatility of these rugs extends to their application in diverse settings, from luxury homes to high-traffic commercial spaces, where they serve both functional and aesthetic purposes.