- Overview

- Recommended Products

Product Name |

Good Quality Shaggy Bath Mat Non Slip Chenille Bathroom Carpet Mat for Bathroom Shower Mat |

Technics |

MACHINE MADE |

Pattern |

Solid |

Material |

Microfiber |

Product name |

Chenille Bath Mat |

Function |

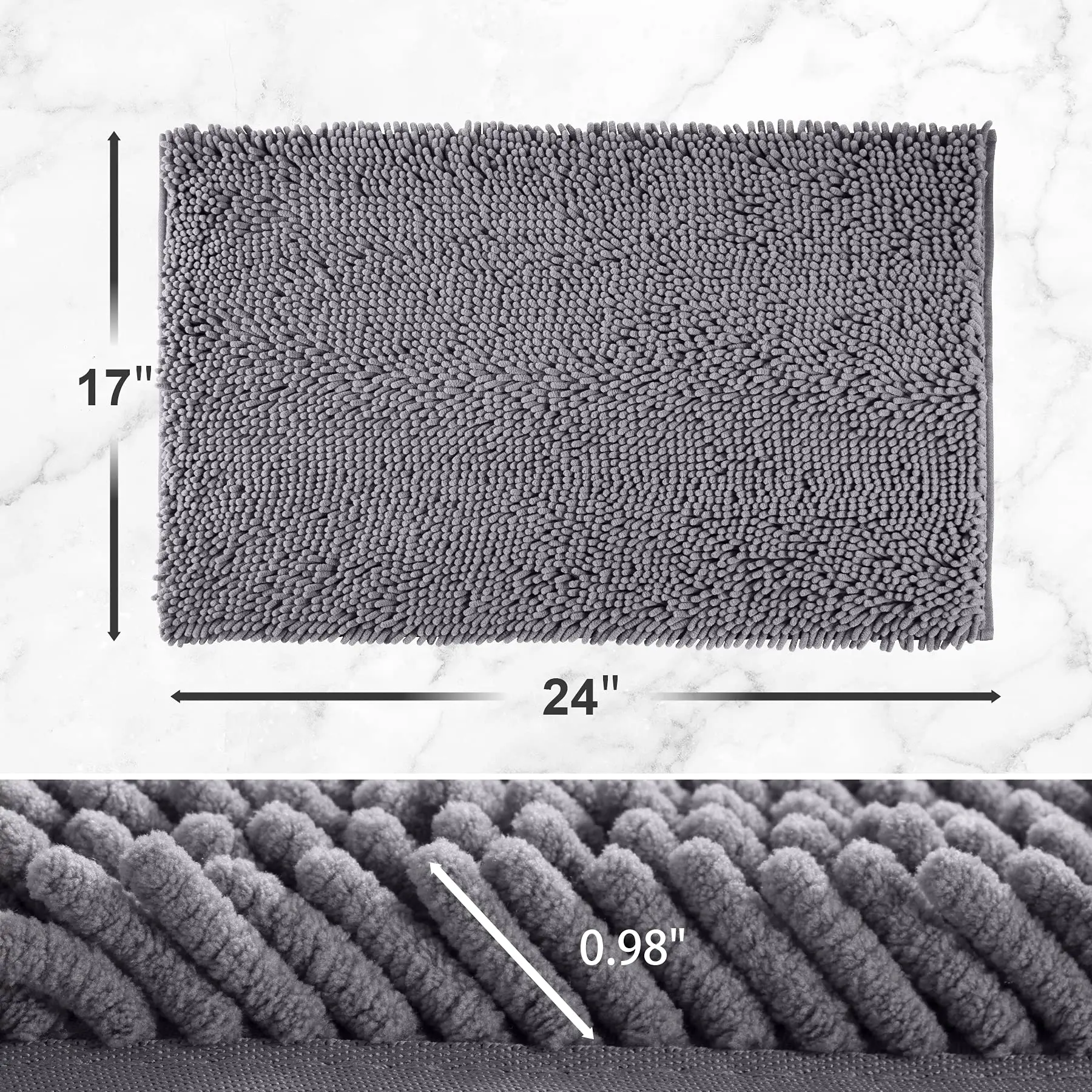

Anti-slip Water Absorbtion Decoration |

Usage |

bathrom/living room/bedroom |

Color |

Customized Color |

Surface material |

Chenille |

Backing material |

Hot Melt Rubber |

Certification |

BSCI |

Non Slip Solid Chenille Water Absorption Shaggy Rug Chenille bath mat

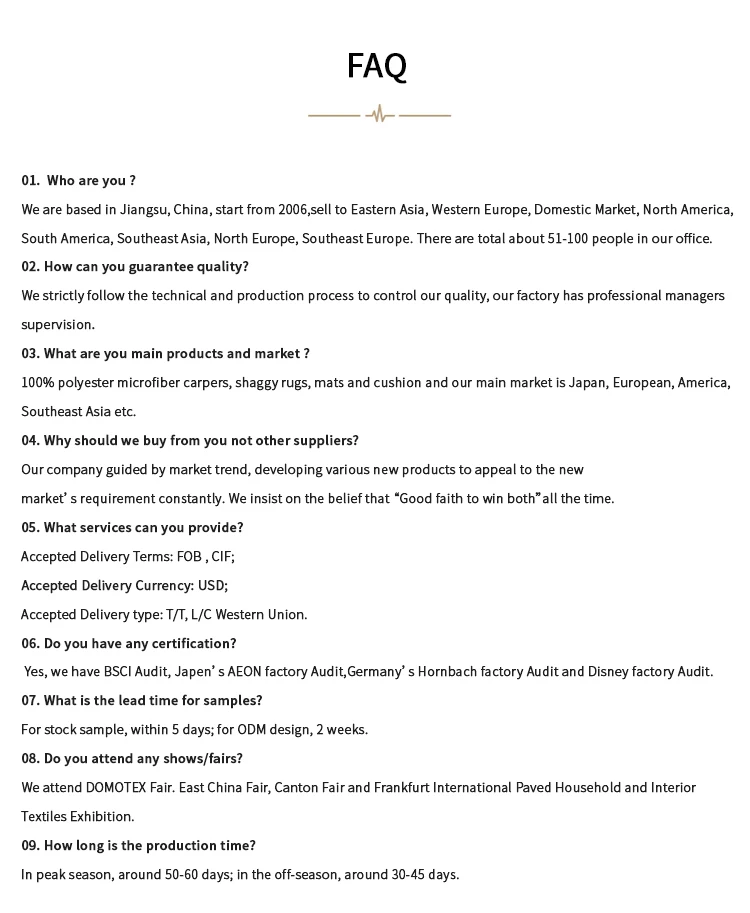

Thickness.

In the fluffy state, the overall height of the product is 1.4inch.

Not easy break.

The use of fine weaving method, no wire drawing, no ring off, fiber is not easy to fall off the surface of the mat.

45° Non-slip.

Different ground material,antiskid adgress is different.

Washing and maintenance.

1、Drum Drying

2、Do not dry clean

3、Low temperature and Neutral washing

4、Do not iron

5、Do not bleach

●Before cleaning, can use the vacuum cleaner or gently pat, make the surface dust fall off and then carry on the normal washing.

●Add a little vinegar to the water to soak, keep the color bright and reduce the fading.

●When the washing is done,avoid light to dry.After drying completely, gently flapping the surface to restore its fluffy state.

●Add a little vinegar to the water to soak, keep the color bright and reduce the fading.

●When the washing is done,avoid light to dry.After drying completely, gently flapping the surface to restore its fluffy state.

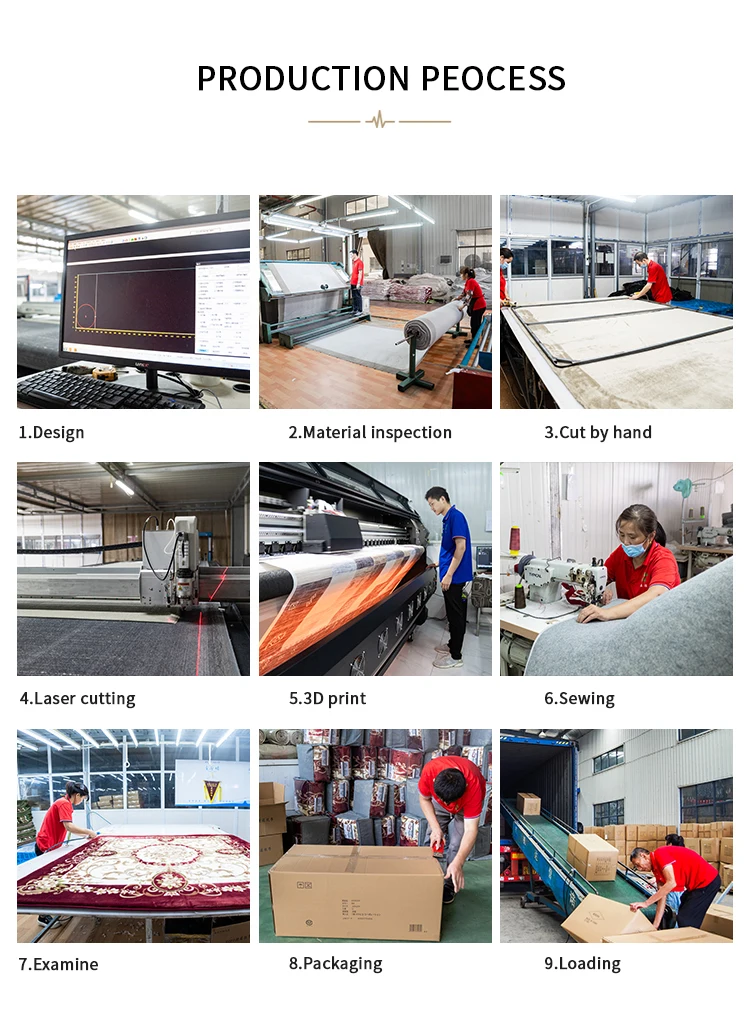

Technological process.

Color proofing:According to the color card provided by you / us for fabric color proofing.

Dyed yarn:After confirming the color sample, customize the fabric and dye.

Compositing:Combine fabric、filler and bottom.

Inspecting:Carry out initial inspection on products, mark and pick out unqualified parts.

Machine tailoring:Use a cutting machine to cut the whole piece to the required size.

Edging:Edging the mat with the specified material.

Quality testing:Carry out quality inspection and Thread cleaning for finished cushions.

Packing:The qualified products shall be packed according to the. requirements and shipped in the cabinet within the specified date.

Compositing:Combine fabric、filler and bottom.

Inspecting:Carry out initial inspection on products, mark and pick out unqualified parts.

Machine tailoring:Use a cutting machine to cut the whole piece to the required size.

Edging:Edging the mat with the specified material.

Quality testing:Carry out quality inspection and Thread cleaning for finished cushions.

Packing:The qualified products shall be packed according to the. requirements and shipped in the cabinet within the specified date.